The Falk Gearbox Catalog is a comprehensive resource detailing high-performance gear drives, offering torque ratings, gear ratios, and lubrication guidelines for industrial applications, ensuring reliability and efficiency.

Overview of the Falk Gearbox Catalog PDF

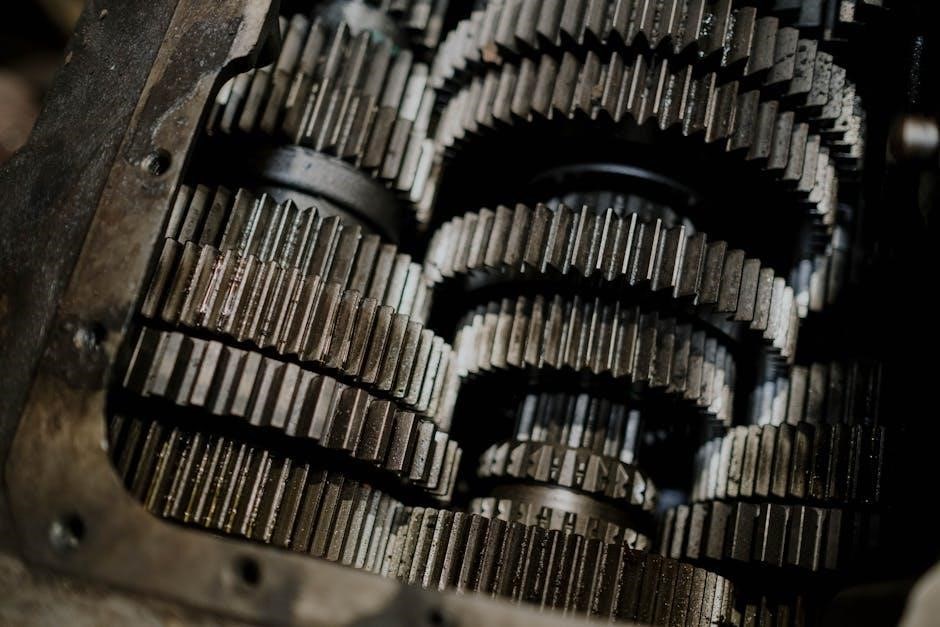

The Falk Gearbox Catalog PDF is a detailed resource that provides comprehensive information on Falk’s range of gear drives, including technical specifications, product features, and application guidelines. It serves as a go-to guide for engineers, technicians, and industry professionals seeking reliable torque management solutions. The catalog includes product brochures, manuals, and datasheets, ensuring users can make informed decisions. Key sections cover gear drive models like the Falk Ultra Max, torque ratings, gear ratios, and lubrication recommendations. The document also highlights Falk’s commitment to quality, with products engineered to meet or exceed AGMA standards. Available for free download, the Falk Gearbox Catalog is an essential tool for optimizing industrial applications, offering insights into efficient and durable gearbox solutions tailored to diverse operational needs.

Importance of the Falk Gearbox Catalog for Industrial Applications

The Falk Gearbox Catalog is indispensable for industrial applications, offering detailed insights into gearbox selection, maintenance, and optimization. It ensures machinery reliability by providing precise specifications, torque ratings, and lubrication guidelines, minimizing downtime and enhancing productivity. Compliance with AGMA standards guarantees high-quality performance, meeting safety and operational demands. The catalog’s lubrication recommendations extend gearbox lifespan and prevent wear, crucial for cost-effective maintenance. Serving as a reference for troubleshooting and maintenance, it aids in ordering parts and performing routine checks. Additionally, it highlights new technologies and models, helping industries stay competitive. Overall, the catalog is a vital tool for optimizing machinery, ensuring efficiency, and reducing operational costs through informed decisions on gearbox selection and upkeep.

Falk Gearbox Product Overview

Falk gearboxes offer a diverse range of high-performance gear drives, including helical, parallel shaft, and right-angle designs, engineered to meet AGMA standards for reliable operation in demanding industrial environments.

Types of Gear Drives Available in the Catalog

The Falk Gearbox Catalog features a wide range of gear drives, including helical concentric, parallel shaft, and right-angle designs. These drives are engineered to meet AGMA standards, ensuring high performance and durability. The catalog also includes shaft-mounted drives, ideal for heavy-duty applications, and specialized models like the Falk Ultra Max and Ultramite series, designed for superior efficiency and extended service life. Each type offers unique benefits, such as high torque capacity, reduced maintenance, and superior lubrication options. With a focus on versatility, Falk gearboxes cater to diverse industrial needs, from standard applications to custom solutions. The catalog provides detailed specifications, making it easier to select the right drive for specific requirements. Whether for pumps, conveyors, or other machinery, Falk’s extensive range ensures reliable operation in demanding environments.

Features and Benefits of Falk Gearboxes

Falk gearboxes are renowned for their durability and high-performance capabilities, making them a preferred choice in industrial applications. One of their key features is the ability to handle high torque loads with minimal vibration, ensuring smooth operation. The gearboxes are designed with advanced lubrication systems, such as Falk Long Term Grease (LTG), which extends re-lubrication intervals and reduces maintenance costs. Additionally, Falk gearboxes are engineered to meet or exceed AGMA standards, ensuring reliability and adherence to industry best practices. Their robust construction and high load-carrying capabilities make them ideal for demanding environments. Furthermore, Falk offers a range of models, including the Ultra Max and Ultramite series, which provide superior efficiency and extended service life. These features not only enhance productivity but also contribute to lower operational downtime, making Falk gearboxes a cost-effective and reliable solution for various industrial needs.

Technical Specifications and Details

The Falk Gearbox Catalog provides detailed torque ratings, gear ratios, and lubrication guidelines, ensuring optimal performance and longevity in industrial applications.

Torque Ratings and Gear Ratios in the Catalog

The Falk Gearbox Catalog provides detailed torque ratings and gear ratios, ensuring optimal performance for various industrial applications. With a 100% overload capacity for starting loads and momentary overloads, Falk gearboxes are engineered to handle demanding conditions. Gear ratios are precisely calculated to meet specific application requirements, offering flexibility and efficiency. The catalog also outlines service factors, such as a unity service factor for electric-motor-driven applications operating under uniform conditions. This ensures reliable operation and minimizes downtime. The torque ratings and gear ratios are designed to meet or exceed AGMA standards, guaranteeing high-quality performance. Whether for standard or custom applications, Falk gearboxes deliver precise power transmission, making them a trusted choice for industries worldwide. The catalog’s technical details enable users to select the right gearbox for their needs, ensuring maximum efficiency and durability.

Lubrication Recommendations for Falk Gearboxes

Proper lubrication is essential for maintaining the performance and longevity of Falk gearboxes. The catalog recommends using Falk Long Term Grease (LTG), which offers superior lubrication, high load-carrying capabilities, and extended re-lubrication intervals. This reduces maintenance costs and downtime significantly. Falk LTG is designed to provide optimal protection against wear and corrosion, ensuring smooth operation under various industrial conditions. Regular lubrication intervals should be followed as specified in the catalog to prevent premature wear. Additionally, it is crucial to avoid mixing different grease types to maintain compatibility and performance. The Falk Gearbox Catalog provides detailed guidelines for lubrication, including quantities and frequencies, to ensure optimal gearbox operation. By adhering to these recommendations, users can maximize efficiency, reduce maintenance, and extend the lifespan of their Falk gearboxes.

Applications and Industries Served

Falk gearboxes serve diverse industries including manufacturing, mining, oil & gas, and material handling, providing reliable solutions for heavy-duty applications and ensuring optimal performance across various sectors.

Common Industries Using Falk Gearboxes

Falk gearboxes are widely used in various industries, including manufacturing, mining, oil & gas, and material handling, where high-torque and durable gear drives are essential. Their reliability and efficiency make them a preferred choice for applications requiring consistent performance. In manufacturing, Falk gearboxes power heavy machinery and production lines, ensuring smooth operations. Mining operations rely on them for conveying systems and crushers, where durability under harsh conditions is critical. Oil & gas industries utilize Falk gearboxes for pumps and compressors, benefiting from their high load-carrying capabilities and extended re-lubrication intervals. Material handling systems, such as bucket elevators and conveyors, also depend on Falk gear drives for efficient material transport. The Falk Ultra Max and V-Class gear drives are particularly popular across these sectors, offering superior lubrication and extended maintenance intervals. With global production facilities, Falk ensures timely support and customization to meet specific industry needs, adhering to AGMA standards for quality and performance.

Case Studies and Success Stories

Falk gearboxes have proven their reliability and performance in numerous industrial applications. A mining operation in Australia successfully implemented Falk Ultra Max gear drives to power heavy-duty crushers, achieving a 30% reduction in downtime and maintenance costs. In the oil & gas sector, a refinery in the Middle East deployed Falk V-Class gear drives for critical pump applications, resulting in improved efficiency and extended equipment lifespan. Additionally, a major material handling company in North America integrated Falk gearboxes into their conveyor systems, benefiting from the Falk Long Term Grease (LTG) technology, which extended re-lubrication intervals and reduced operational disruptions. These success stories highlight Falk’s commitment to delivering high-quality, durable solutions tailored to meet the demands of diverse industries. By adhering to AGMA standards and offering customizable options, Falk continues to build a reputation for excellence in torque management and gear drive technology.

Leave a Reply