Overview of the Kubota D1105 Engine

The Kubota D1105 engine is a robust and efficient 3-cylinder industrial diesel engine, widely recognized for its reliability and performance. Designed for versatility, it delivers 18.5 kW of power, making it suitable for various applications such as tractors, construction equipment, and industrial machinery. Known for its durability and fuel efficiency, the D1105 engine has become a popular choice for professionals seeking a dependable power source. Its compact design and ease of maintenance further enhance its appeal, ensuring optimal productivity in demanding environments. The engine’s reputation for consistent performance has solidified its position as a trusted option across multiple industries.

1.1. Key Specifications and Features

The Kubota D1105 engine is a 3-cylinder, vertically oriented, water-cooled diesel engine designed for industrial and agricultural applications. It boasts a displacement of 1.1 liters and delivers a maximum power output of 18.5 kW (24.8 HP) at 2,400 rpm. This engine is renowned for its compact size, durability, and fuel efficiency, making it a preferred choice for various machinery, including tractors, generators, and construction equipment.

One of the standout features of the D1105 engine is its robust construction. The engine block and cylinder head are made from high-strength cast iron, ensuring longevity and resistance to wear and tear. Additionally, the engine incorporates a direct fuel injection system, which enhances combustion efficiency and reduces fuel consumption. This system also contributes to lower emissions, making the D1105 an environmentally friendly option.

The engine is equipped with a single-stage turbocharger, which improves performance at higher loads and elevations. Furthermore, the D1105 features a mechanical fuel injection pump and a gear-driven timing system, both of which are designed for reliability and ease of maintenance. The engine’s cooling system is also noteworthy, as it includes a water-cooled design with a radiator and fan, ensuring optimal temperature regulation even in demanding conditions.

In terms of dimensions, the Kubota D1105 is compact, measuring approximately 460 mm in length, 380 mm in width, and 550 mm in height. Its dry weight is around 125 kg, making it lightweight enough for installation in a variety of machinery without compromising power output. The engine’s compactness and lightweight design make it an ideal solution for applications where space and weight are critical factors.

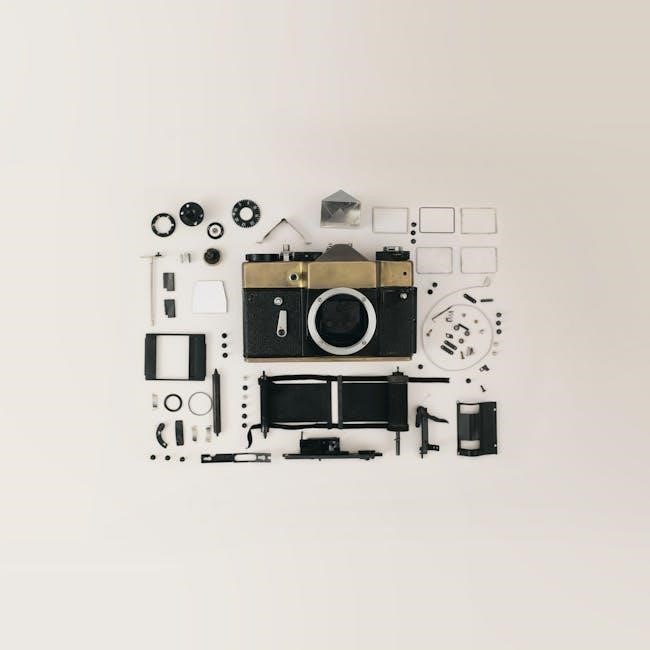

Another key feature of the D1105 is its ease of maintenance; The engine is designed with accessible service points, allowing users to perform routine checks and repairs efficiently. The parts manual provides detailed diagrams and instructions, ensuring that owners and technicians can identify and replace components with minimal downtime. This accessibility not only reduces maintenance costs but also extends the engine’s service life.

Overall, the Kubota D1105 engine is a well-rounded powerplant that combines performance, efficiency, and durability. Its specifications and features make it suitable for a wide range of applications, from small-scale agriculture to industrial machinery. Whether you’re powering a tractor, generator, or other equipment, the D1105 delivers consistent and reliable performance, making it a trusted choice for professionals worldwide.

1.2. Common Applications and Usage

The Kubota D1105 engine is a versatile powerplant that finds applications in a wide range of industries and machinery. Its compact design, fuel efficiency, and reliable performance make it an ideal choice for both agricultural and industrial use. Below are some of the most common applications and usage scenarios for the Kubota D1105 engine.

Agricultural Machinery

One of the most common applications of the Kubota D1105 engine is in agricultural machinery. It is widely used to power tractors, harvesters, and other farm equipment. The engine’s compact size and high torque output make it suitable for small to medium-scale farming operations. Farmers appreciate its durability and ability to handle demanding tasks such as plowing, planting, and transporting crops. Additionally, the engine’s fuel efficiency helps reduce operational costs, making it a cost-effective solution for agricultural needs.

Construction Equipment

The Kubota D1105 engine is also frequently used in construction machinery, including mini excavators, skid-steer loaders, and compact wheel loaders. Its lightweight design and high power output allow it to perform effectively in tight spaces and challenging environments. The engine’s reliability ensures minimal downtime, which is critical for construction projects where time is of the essence. Its compact dimensions also make it easier to integrate into various types of construction equipment without compromising performance.

Generators and Power Generation

Another common application of the Kubota D1105 engine is in generator sets. Its consistent power output and fuel efficiency make it an excellent choice for both standby and prime power generation. The engine’s durability and low maintenance requirements ensure that it can provide reliable power in remote or off-grid locations. This makes it a popular choice for businesses, hospitals, and other facilities that require a dependable power source.

Industrial Machinery

In industrial settings, the Kubota D1105 engine is used to power a variety of machinery, including pumps, compressors, and material handling equipment. Its compact size and high power density make it an ideal solution for industrial applications where space is limited. The engine’s robust design and ease of maintenance also make it a favorite among industrial users who prioritize reliability and longevity.

Specialized Vehicles

The Kubota D1105 engine is also used in specialized vehicles, such as utility carts, golf carts, and small transport vehicles. Its lightweight and fuel-efficient design make it an excellent choice for these types of vehicles. The engine’s compact size and ease of integration allow manufacturers to create vehicles that are both functional and environmentally friendly.

1.3. Why the D1105 is Reliable

The Kubota D1105 engine is renowned for its reliability, a trait that has made it a favorite among professionals and machinery operators worldwide. This reputation stems from several key factors, including its robust design, advanced engineering, and commitment to quality. Below, we explore the reasons behind the D1105’s reliability and why it remains a trusted choice for various applications.

Robust Design and Durable Construction

At the heart of the Kubota D1105 engine’s reliability is its robust design and durable construction. Built with high-quality materials and precision engineering, the engine is designed to withstand the rigors of demanding environments. Whether it’s used in agricultural machinery, construction equipment, or industrial applications, the D1105 is built to endure. Its compact size and lightweight design do not compromise its strength, ensuring that it can handle heavy workloads without faltering.

Advanced Engineering and Technology

Kubota’s commitment to innovation is evident in the D1105 engine. Equipped with advanced technologies such as a direct fuel injection system and a precision-engineered combustion chamber, the engine delivers exceptional performance while maintaining fuel efficiency. These features not only enhance reliability but also ensure that the engine operates smoothly under various conditions. The D1105’s ability to maintain consistent power output, even in challenging environments, further solidifies its reputation for dependability.

Ease of Maintenance and Accessibility

Another key factor contributing to the D1105’s reliability is its ease of maintenance. Kubota has designed the engine with serviceability in mind, making it easier for users to perform routine maintenance and repairs. The availability of a comprehensive parts manual, such as the Kubota D1105 parts manual PDF, ensures that users can quickly identify and replace components as needed. This accessibility not only reduces downtime but also extends the engine’s lifespan, making it a cost-effective solution for long-term use.

Proven Track Record and User Feedback

The Kubota D1105 engine has a proven track record of reliability, with countless users vouching for its performance over the years. Positive feedback from professionals in agriculture, construction, and other industries highlights the engine’s ability to deliver consistent results. This widespread acceptance and satisfaction further underscore the D1105’s reputation as a reliable powerplant. Users appreciate its durability, fuel efficiency, and ease of maintenance, making it a preferred choice for their machinery.

Comprehensive Support and Resources

Kubota’s commitment to customer support also plays a significant role in the D1105’s reliability. The company provides extensive resources, including detailed parts manuals, maintenance guides, and troubleshooting tips, to help users keep their engines in optimal condition. The availability of genuine Kubota parts ensures that any repairs or replacements are done to the highest standards, further enhancing the engine’s reliability and performance.

The Importance of the Kubota D1105 Parts Manual

The Kubota D1105 parts manual is an essential resource for anyone maintaining or repairing this engine. It provides detailed information on parts identification, ordering, and installation, ensuring accuracy and efficiency. The manual includes diagrams, part numbers, and descriptions, making it easier to locate and replace components. This resource is crucial for preventing errors during repairs and reducing downtime. By following the manual, users can ensure proper maintenance, extend the engine’s lifespan, and maintain its performance. Additionally, the manual aids in troubleshooting, helping users identify and resolve issues quickly. Its availability in formats like PDF and DVD ensures accessibility, making it a vital tool for engine owners and technicians alike.

2.1. What the Manual Includes

The Kubota D1105 parts manual is a comprehensive resource designed to provide users with detailed information about every component of the engine. It includes a complete list of parts, including part numbers, descriptions, and diagrams, making it easier to identify and order the correct components. The manual also features hydraulic diagrams, which are essential for understanding the engine’s hydraulic system and troubleshooting any issues that may arise. Additionally, it contains maintenance schedules, service guidelines, and repair procedures, ensuring that users can perform routine upkeep and address problems effectively.

The manual is available in formats such as PDF and DVD, offering users flexibility in how they access the information. The PDF version is particularly convenient, as it can be easily stored on digital devices and accessed on the go. The manual also includes advanced features like geolocation, smart alerts, and customizable themes, which enhance the user experience and make it easier to navigate. These features allow users to set reminders for maintenance tasks and receive notifications when parts need to be replaced, ensuring the engine remains in optimal condition.

One of the key aspects of the manual is its focus on troubleshooting. It provides step-by-step instructions for diagnosing common issues, which helps users resolve problems quickly and efficiently. This not only saves time but also reduces the risk of further damage to the engine. The manual also includes a detailed parts catalog, which lists every component of the engine, along with its specifications and compatibility. This ensures that users can order the correct parts without confusion, avoiding delays in repairs or maintenance.

Furthermore, the manual includes sections on installation and assembly, which are crucial for users who need to replace or upgrade parts. These sections provide clear instructions and diagrams, guiding users through the process step by step. The manual also covers safety precautions, ensuring that users can perform maintenance and repairs safely and effectively. By following the guidelines outlined in the manual, users can extend the lifespan of their engine and maintain its performance over time.

2.2. How It Aids in Maintenance and Repair

The Kubota D1105 parts manual is an essential tool for maintaining and repairing the engine efficiently. It provides a comprehensive guide that helps users identify and address potential issues promptly, ensuring the engine operates at peak performance. One of the key ways the manual aids in maintenance is by outlining a detailed maintenance schedule. This schedule specifies the recommended intervals for tasks such as oil changes, filter replacements, and inspections, helping users keep track of routine upkeep. By following these guidelines, users can prevent minor issues from escalating into major problems, thereby extending the engine’s lifespan.

When it comes to repairs, the manual offers step-by-step instructions for diagnosing and fixing common faults. It includes troubleshooting sections that guide users through identifying symptoms, locating the source of the problem, and implementing the appropriate solution. This eliminates guesswork and reduces the time spent on repairs. The manual also provides detailed diagrams and exploded views of engine components, making it easier to understand how parts interact and where they are located. This visual guidance is particularly useful for individuals who are less familiar with the engine’s internal workings.

The parts catalog within the manual is another critical feature for maintenance and repair. It lists every component of the engine, along with its part number, description, and compatibility. This ensures that users can order the correct replacement parts without confusion or delays. The catalog is organized in a logical manner, allowing users to quickly locate the information they need. This level of specificity is invaluable when dealing with complex machinery like the Kubota D1105, where using the wrong part could lead to further damage or safety hazards.

In addition to maintenance and repair guidance, the manual includes safety precautions to ensure that users can perform tasks without risking injury or causing damage to the engine. These precautions are clearly outlined and emphasize the importance of proper tools, protective equipment, and working conditions. By adhering to these guidelines, users can maintain a safe and efficient workflow, even when tackling complex repairs. The manual’s focus on safety underscores Kubota’s commitment to user well-being and engine longevity.

Furthermore, the manual’s availability in digital formats such as PDF and DVD makes it highly accessible. Users can store the manual on their computers, tablets, or smartphones, allowing them to access critical information anywhere, anytime. This convenience is especially beneficial for professionals who work in remote locations or need to troubleshoot issues on-site. The digital format also enables users to search for specific keywords or part numbers quickly, saving time and effort during maintenance and repair tasks.

2.3. Necessity for Engine Owners

The Kubota D1105 parts manual is an indispensable resource for engine owners, offering unparalleled value for maintaining, repairing, and extending the lifespan of the engine. Whether you are a professional mechanic, a seasoned operator, or a new owner, the manual serves as a cornerstone for understanding and caring for the Kubota D1105. Its necessity stems from the comprehensive information it provides, which is tailored to ensure optimal performance, reduce downtime, and minimize repair costs.

One of the primary reasons the manual is essential for engine owners is its ability to empower them with knowledge. The Kubota D1105 parts manual is not just a technical document; it is a guide that bridges the gap between the engine’s complex design and the user’s need for practical understanding. By providing detailed diagrams, exploded views, and clear instructions, the manual allows owners to identify components, understand their functions, and perform routine maintenance with confidence. This level of transparency ensures that owners are not reliant on external assistance for every minor task, thereby saving time and resources.

Another critical aspect of the manual’s necessity is its role in preventing costly mistakes. Without the manual, identifying the correct parts for replacement or troubleshooting issues can be a daunting task, especially for those unfamiliar with the engine’s inner workings. The parts catalog, included in the manual, lists every component with its corresponding part number, ensuring that owners can order the exact replacements needed. This specificity eliminates the risk of purchasing incorrect parts, which could lead to further damage or safety hazards. By adhering to the manual’s guidelines, owners can avoid unnecessary expenses and ensure that repairs are done right the first time.

The manual is also a vital tool for maintaining the engine’s performance and longevity. Regular maintenance is crucial for preventing wear and tear, and the manual provides a detailed schedule to help owners stay on track. From oil changes and filter replacements to belt inspections and coolant checks, the manual outlines the steps necessary to keep the engine running smoothly. By following these recommendations, owners can maximize fuel efficiency, reduce emissions, and extend the engine’s operational life. This proactive approach not only saves money but also ensures that the engine remains reliable in demanding work environments.

Furthermore, the Kubota D1105 parts manual is a future-proof investment for engine owners. As engines age, parts become scarce, and repair information may become harder to find. The manual serves as a permanent reference, providing a wealth of information that remains relevant even as technology advances. Whether you plan to keep the engine for years or eventually sell it, the manual adds value by ensuring that the engine is well-maintained and repairable, making it more attractive to potential buyers.

Leave a Reply